Projects

LPG Capacity Upgrade

Project Synopsys

Increase LPG throughput to city's underground LPG reticulation system to meet growing market demand.

Project Highlights

- Development of Process Flow Diagrams (PFDs) and Heat & Material Balances (H&MB).

- Comprehensive plant design and P&ID development in compliance with AS/NZS 1596 standard.

- Line and equipment unit sizing, specification, and selection, including:

- LPG vaporizers and pumps.

- Gas fired water boilers and pumps.

- Flow control valves and pressure regulators.

- Facilitation of the HAZOP workshops to ensure safety and operability.

The Outcome

A fully automated, safe and reliable plant, that supplies LPG to city's underground reticulation pipework, with built-in flexibility to adapt to fluctuations in demand.

Natural Gas Import FEED Study

Project Synopsys

Design and develop a natural gas supply and transportation system from two separate sources to a chemical manufacturing plant. The system includes over 7 km of pipelines, as well as gas mixing and delivery stations.

Project Highlights

- Conducted process simulations to predict pressure drop, flow rate, line velocities, and mixed gas composition, determining appropriate pipeline sizes.

- Performed line and equipment sizing calculations, including for flow and pressure control valves, mass flow meters, and volumetric flow meters.

- Compliance with AS/NZS 2885 standards series for high pressure gas and liquid petroleum pipelines.

- Developed Process Flow Diagrams (PFDs) and Heat & Material Balances (H&MBs).

- Created detailed Piping and Instrumentation Diagrams (P&IDs).

- Established a comprehensive Process Control Philosophy.

- Provided Process Engineering support during HAZOP workshops and implemented resulting actions to ensure safety and compliance.

The Outcome

The FEED study provided sufficient detail to enable the client to develop a high-confidence cost estimate. This allowed the client to make an informed decision on whether to proceed to the Detailed Design phase and finalize contractual arrangements.

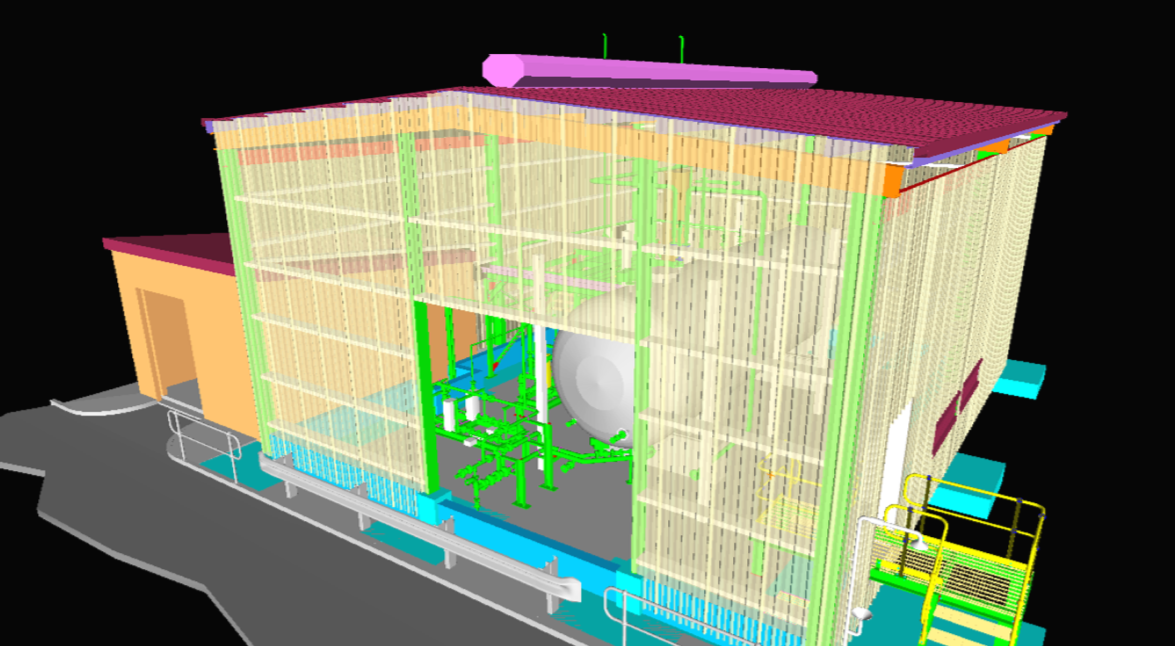

Aqueous Ammonia Plant in a Power Station

Project Synopsys

The existing plant utilized an anhydrous ammonia process to produce a diluted aqueous ammonia solution for corrosion prevention in plant boilers. However, this process posed significant health, safety, and environmental (HS&E) risks due to the storage and handling of anhydrous ammonia. The client sought a safer design to minimize these risks while maintaining operational efficiency.

The Solution

A comprehensive engineering solution was delivered, consisting of:

- Concept Studies: Identified key risks and defined a safer approach.

- Detailed Plant Design: Created a new aqueous ammonia plant capable of:

- Receiving and storing a concentrated aqueous ammonia solution.

- Diluting the concentrated solution to any required strength.

- Transferring the diluted aqueous ammonia solution to the boilers' day tanks on demand.

- Facilitation of the HAZOP workshop to ensure safety and operability.

The new plant design is fully automated, operating 24/7 without the need for on-site personnel.

The Outcome

The resulting plant offers the same functionality as the previous anhydrous ammonia system but with significantly reduced risks to health, safety, and the environment. Key benefits include:

- Improved safety for both plant personnel and surrounding communities.

- Enhanced environmental compliance.

- Reliable, unmanned operation ensuring consistent product availability.

Energy Generation FEED Study

Relocation and Conversion of Diesel-Fired Electric Turbines to Gas-Fired Electric Turbines

Project Synopsys

The client aimed to relocate several 50 MW diesel-fired electric turbine units to a new site connected to a natural gas supply. The scope included developing a cost estimate for the relocation and conversion of the diesel operated turbines to gas-fired operation, leveraging the local natural gas supply.

Project Highlights

- Conducted process design, computational fluid dynamics simulations, and process flow calculations.

- Designed natural gas transmission pipelines, gas treatment and metering systems, and custody gas transfer systems.

- Ensured standard compliance with ASME B31.1 (Power Piping) and AS/NZS 2885 standards series for high-pressure gas and liquid petroleum pipelines.

- Developed 'Balance of plant' systems including; demineralized water, oily water, wash water, and fire water systems.

The Outcome

The FEED study delivered sufficient detail and a high-confidence cost estimate, enabling the client to make informed decisions on proceeding to the Detailed Design phase and finalizing contractual arrangements.

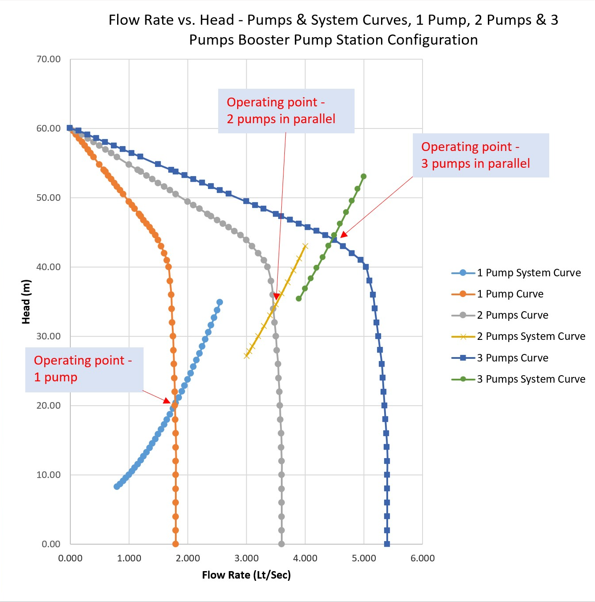

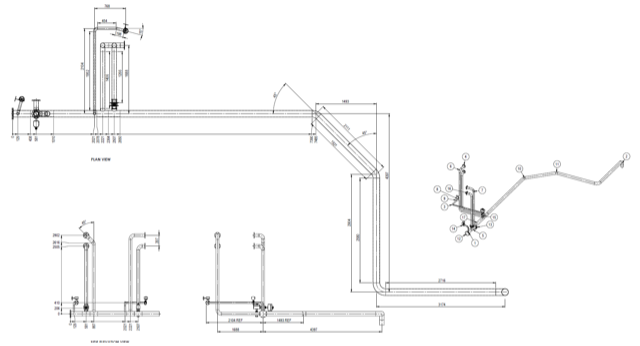

Pressure Sewer System

Hydraulic Modelling and Flow Computation for Sewer Pump Station

Single, Duplex and Triplex Pump Configuration

Project Synopsys

Dozens of tenements in a remote shire area were not connected to the main sewer system and relied on septic tanks. Sewage from these tanks was pumped into evaporation ponds, creating significant environmental and odor issues. The tenements were distributed over a vast geographical area, presenting complex design challenges, including:

- Distance: Over 4 kilometers between tenements and the sewage treatment plant.

- Elevation differences: Significant height variances made sewage transfer more complex.

The Solution

A comprehensive Pressure Sewer System design was developed to address these challenges. Key elements of the solution included:

- Conducting supplier reviews and benchmarking.

- Specifying and selecting equipment units on behalf of the council.

- Designing a system to enable continuous discharge and transfer of sewage from tenements to the treatment plant.

The Outcome

The new system delivered significant improvements:

- Environmentally safe sewage transfer.

- A long-lasting solution with minimal maintenance.

- Odor-free operation for improved community living conditions.

Demineralising Water Pre-treatment Plant Optimization

Project Synopsys

The Demineralising Water Pre-treatment Plant at a power station included a clarifier and a coagulant dosing system, originally designed to remove suspended solids, color, and organic matter. However, the system's design flaws led to:

- Pollution of treated water with dissolved and undissolved coagulant particles and lumps.

- Increased load on sand filters and ion exchange resins, resulting in frequent backwashing and column regeneration.

- Excessive usage of filtered water and chemicals.

- Increased downtime for plant operators and unnecessary financial losses.

The Solution

- Concept and Feasibility Studies: Analyzed the root causes and potential solutions.

- Detailed Process and Mechanical design: Replaced the clarifier and coagulant dosing system with carbon break tank filters, which eliminated the need for sand filters. Specific items included:

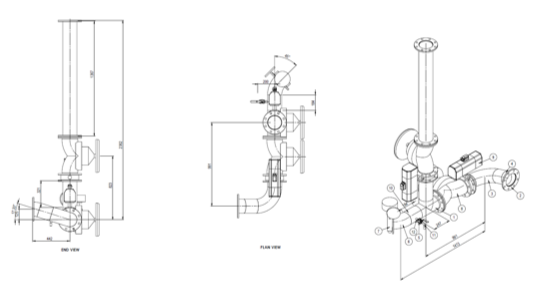

- Detailed P&IDs

- Hydraulic calculations

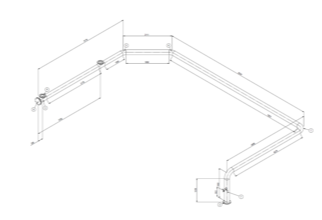

- Mechanical piping design, 3D plant modelling and isometrics drawings

- Equipment unit sizing and selection, MTOs (material take-off) and overall job cost estimate

The Outcome

- Simplified operations with reduced maintenance requirements.

- Lower operational costs due to reduced chemical and water consumption.

- Improved reliability and efficiency, leading to long-term savings.

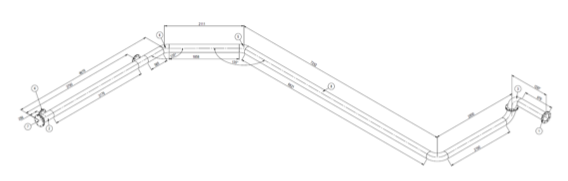

Liquid Chocolate Production Capacity Upgrade

Project Synopsys

The chocolate production process was labor-intensive, required excessive man-hours, and struggled to meet growing market demand.

The Solution

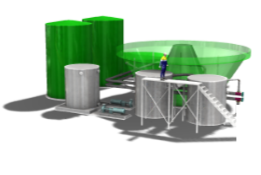

The project involved upgrading and optimizing the production system:

- Melting System Upgrade

Replaced existing small size chocolate block melters with 1-ton block melting units, capable of melting multiple 1-ton solid chocolate blocks concurrently. Calculations and design work included:

- Steam consumption and heat load calculations.

- Heat and mass balances.

- A 90°C closed-loop hot water transportation system.

- Pressure drop calculations, line and pump sizing.

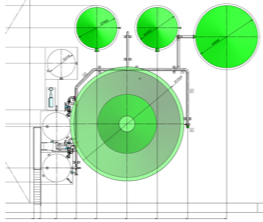

- Liquid Chocolate Storage and Transportation

Added dimple storage tanks and liquid chocolate transportation lines with hot water tracing system. Design considerations included:

- Heat load and heat transfer calculations.

- Hot water system hydraulics and annulus flow.

- Line and pump sizing.

- Net Positive Suction Head (NPSH) calculations.

- Blending and Cooling System

Installed liquid chocolate blend tanks to cool the chocolate for proper nitrogen-blow solidification before ice-cream dipping. Design efforts included:

- Blend tank sizing and specifications.

- Optimization of operating parameters such as agitator RPM, cooling water flow rate, and feed temperature.

- Heat pump unit rating and specification.

The Outcome

The upgrades resulted in:

- Reduced labor requirements and man-hours.

- Increased production throughput to meet market demand.

- Consistent final product quality and desired characteristics.

Food Grade CO₂ Plant

Project Synopsys

Production of food-grade CO₂ from off-gas stream of a fermentation plant.

Project Highlights

- Apply thermodynamic principles to design CO₂ gas purification and liquefaction systems.

- Design the refrigeration cycle.

- Develop PFDs (Process Flow Diagrams) and H&MB (Heat and Material Balances).

- Carry out P&ID (Piping and Instrumentation Diagram) development.

- Size and specify equipment units, including:

- High-pressure purification equipment for raw CO₂ gas.

- CO₂ compressors and refrigerant compressor.

- Condenser, evaporator, reboiler, and stripper.

- Liquid CO₂ transfer equipment and storage tanks.

- Produce equipment and instrument data sheets and liaise with suppliers during the purchasing phase.

- Manage the cross-disciplinary design effort.

- Produce System Functional Description.

The Outcome

Fully automated, safe and reliable plant, producing and storing food grade liquid CO₂ with the flexibility to adapt to the fluctuation in off-gas supply from the fermentation plant.